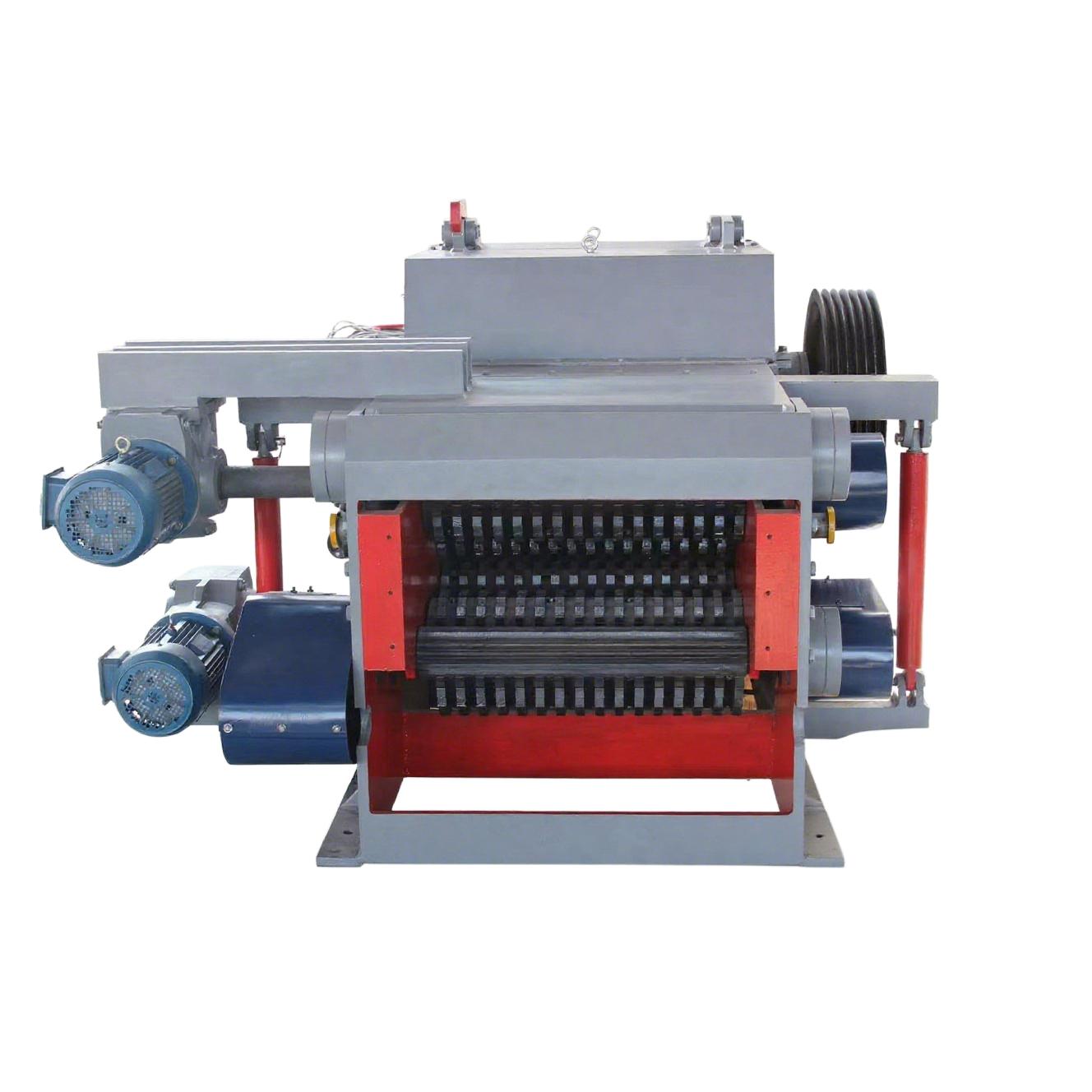

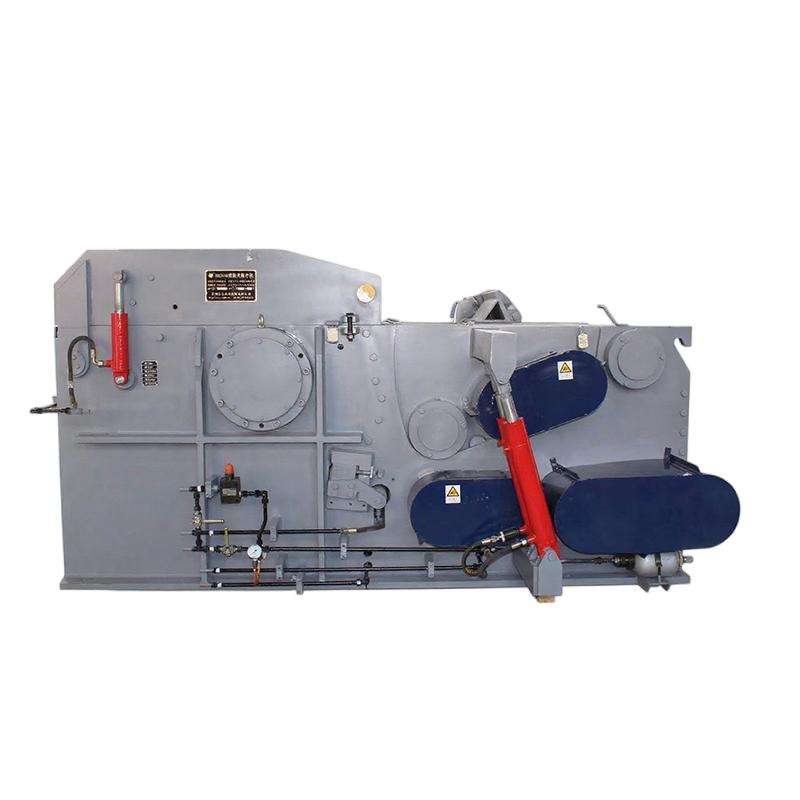

Drum chipper

Drum chippers are key pre-processing equipment in feed production. Their core working component is a high-speed rotating drum equipped with flying knives. These knives, acting in shearing action with bed knives, cut long-fiber materials like straw and grass into uniformly sized pieces. This equipment features a sturdy structure, high production capacity, and stable operation. It effectively meets the material form requirements of subsequent processes and is a crucial component in ensuring high-quality feed production.