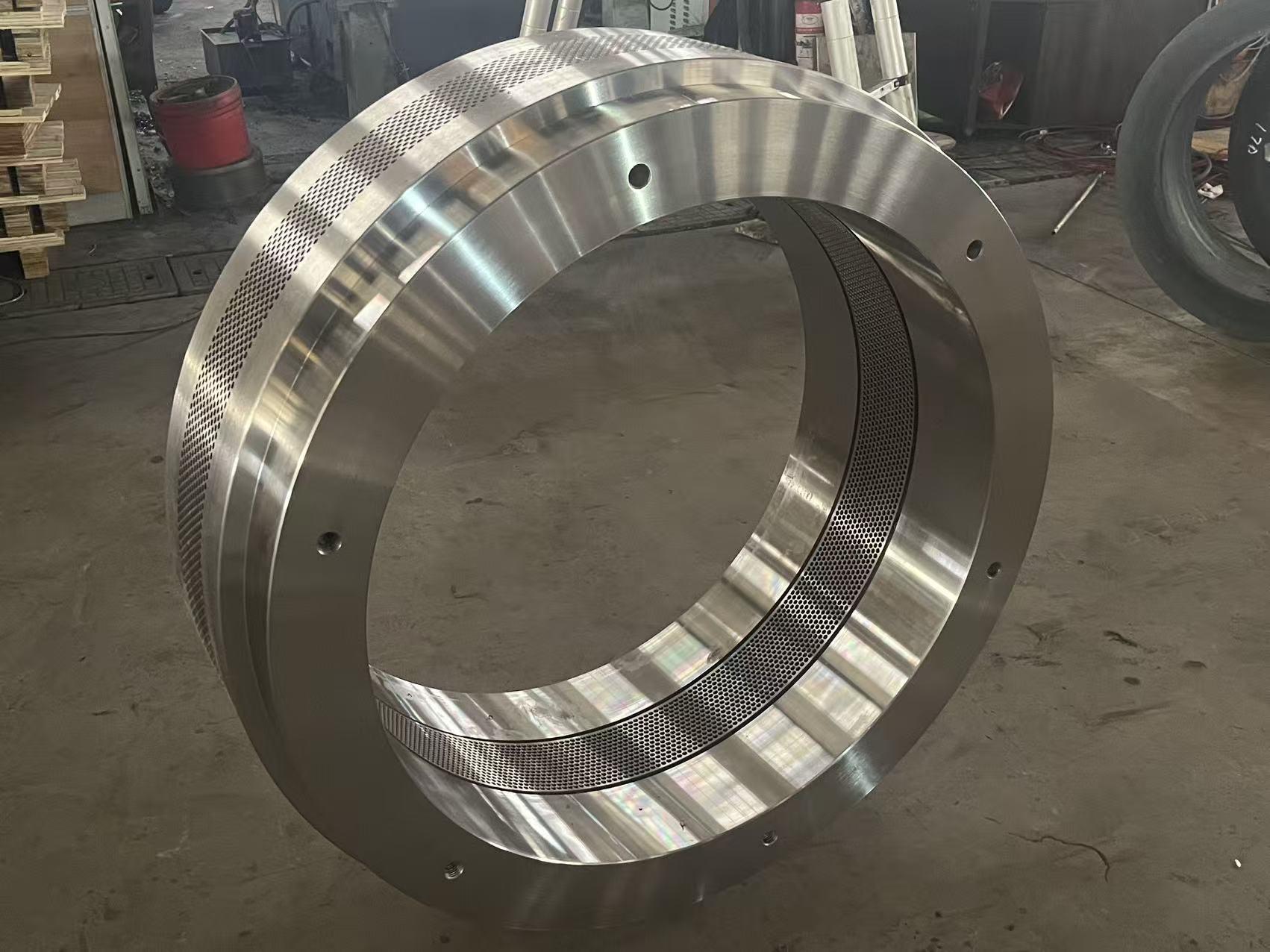

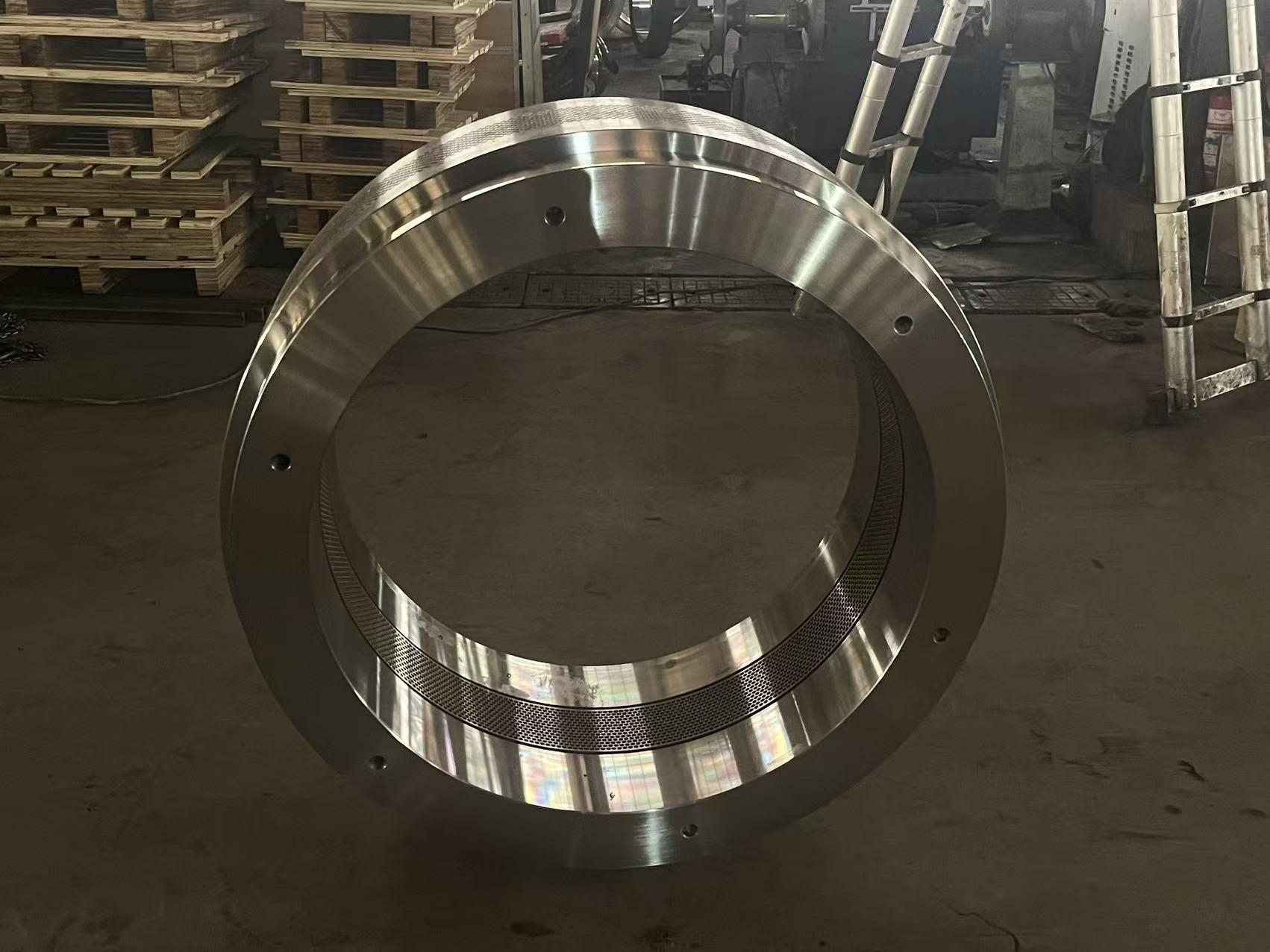

JARAY Manufactures a CPM 7932-5 Biomass Pellet Mill Ring Die for a Brazilian Customer

Supporting Efficient and Stable Biomass Pellet Production in Brazil

With the continuous global demand for renewable energy, biomass pellet fuel is playing an increasingly important role in Brazil’s energy structure. To meet local customers’ requirements for high capacity, stability, and long service life of pellet mill components, JARAY successfully customized and manufactured a CPM 7932-5 biomass pellet mill ring die for a Brazilian customer, which has now been put into operation.

1. Project Background

Brazil has abundant forestry and agricultural resources, including wood chips, sawdust, and sugarcane bagasse. The customer operates a CPM 7932-5 biomass pellet mill and placed high demands on the ring die in terms of wear resistance, pellet forming efficiency, and service life.

Based on the customer’s raw material characteristics and operating conditions, JARAY’s technical team worked closely with the client to define the ring die material, hole structure, and manufacturing standards, ensuring full compatibility with on-site production requirements.

2. CPM 7932-5 Biomass Pellet Mill Ring Die – Product Description

The CPM 7932-5 ring die supplied by JARAY was custom-designed in accordance with the original machine specifications and optimized for biomass pellet production.

Key Features:

-

High-Quality Wear-Resistant Alloy Steel

Manufactured from high-strength alloy steel specifically developed for biomass pelleting, offering an excellent balance of wear resistance and toughness for long-term processing of fibrous materials. -

Precision Hole Pattern and Compression Ratio Design

Hole diameter, hole geometry, and compression ratio were optimized according to the customer’s raw materials, improving pellet forming rate and density. -

Advanced Heat Treatment Process

Multiple heat treatment stages ensure uniform hardness throughout the ring die, reducing the risk of cracking and abnormal wear. -

High Machining Accuracy and Operational Stability

Strict control of concentricity and flatness ensures smooth cooperation with the rollers and stable pellet mill operation.

3. Application Performance

After commissioning, the CPM 7932-5 biomass pellet mill ring die demonstrated excellent performance:

-

Stable pellet forming with consistent product quality

-

Improved production efficiency and reduced energy consumption

-

Significantly enhanced wear resistance and extended service life

-

Smooth machine operation with reduced maintenance frequency

The customer expressed high satisfaction with the product quality and JARAY’s technical support.

4. JARAY’s Expertise

JARAY specializes in the research, development, and manufacturing of pellet mill ring dies, rollers, and other core wear parts. JARAY products are widely exported to South America, Europe, Southeast Asia, and other regions. With mature manufacturing processes, a comprehensive quality management system, and extensive export experience, JARAY provides customized biomass pelleting solutions tailored to different raw materials, machine models, and operating conditions.

Conclusion

The successful delivery of the CPM 7932-5 biomass pellet mill ring die for a Brazilian customer demonstrates JARAY’s technical strength and commitment to quality in the biomass pelleting industry. JARAY will continue to supply high-quality, reliable pellet mill components to customers worldwide.