High-Quality Feed Machinery Components Arrive in Vietnam in Batches, Supporting the Upgrading of Spain’s Livestock Industry

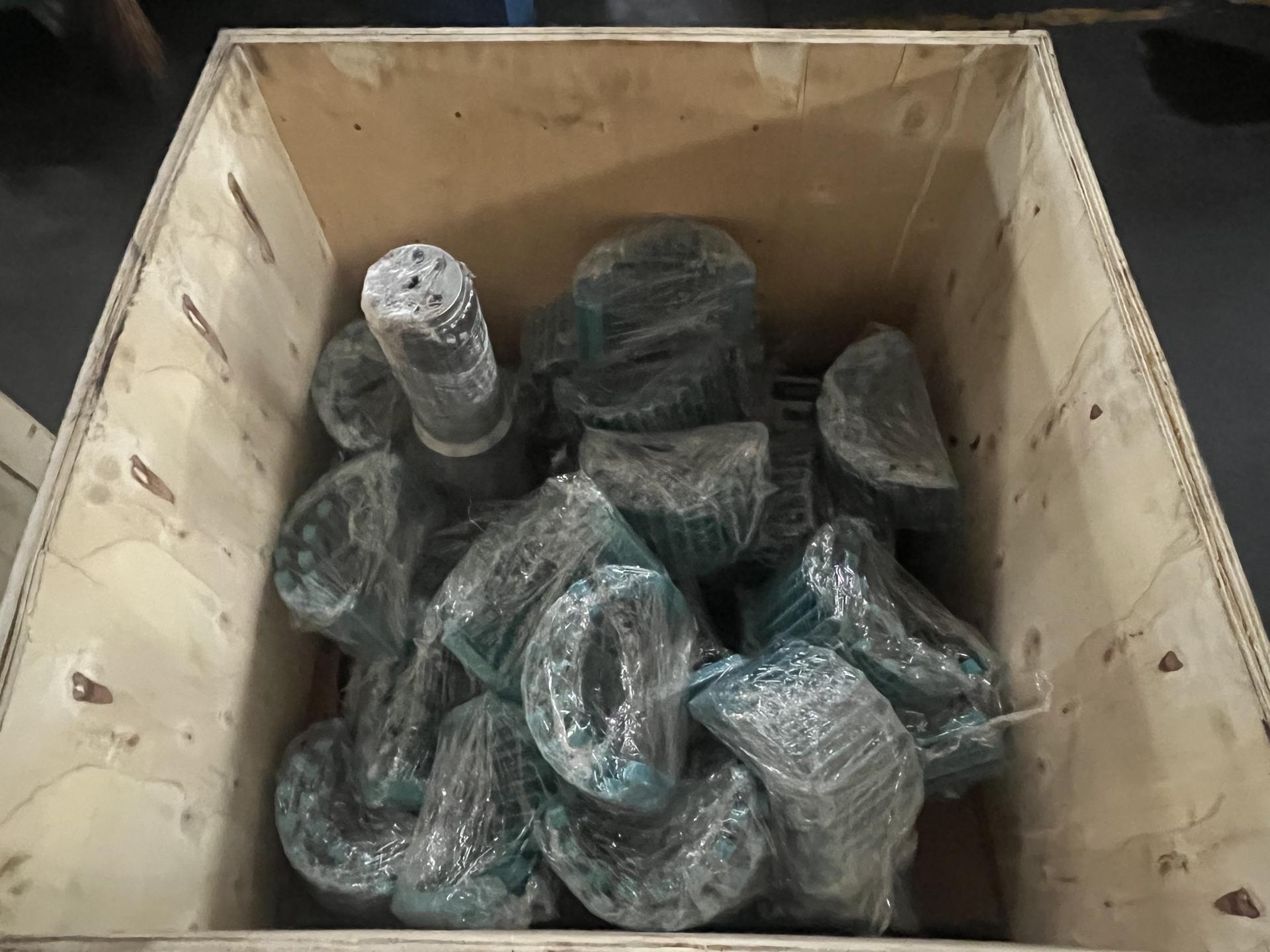

[Liyang, Jiangsu, China, July 28] Core components for feed machinery manufactured by Jereh Machinery Manufacturing Plant—ring dies, roller assemblies, pellet mill accessories, and tungsten carbide hammers—have been packaged and shipped to Spain. This order covers key components for feed production lines, providing Spanish customers with efficient and durable equipment support, helping to improve the quality and efficiency of the local livestock and feed processing industries.

High-Standard Components Ensure Production Efficiency

The components shipped to Spain include:

Ring Dies and Roller Assemblies: Forged from high-quality alloy steel, heat-treated and precision-machined, they possess excellent wear resistance and customizable compression ratios, suitable for pelleting needs of different materials, significantly improving pelleting rate and output.

Pellet Mill Wear Parts: Includes a complete set of maintenance accessories, ensuring long-term stable operation of customer equipment and reducing downtime losses.

Tungsten Carbide Hammers: Designed specifically for crushers, they have high hardness and strong impact resistance, with a service life more than three times that of ordinary hammers, greatly reducing the frequency and cost of replacement for customers.

All components undergo multiple quality inspections before shipment, including hardness testing and dynamic balance testing, and meet international standards.