China’s high-end ring die manufacturer successfully delivers customized ring dies to Europe, boosting global feed industry upgrades.

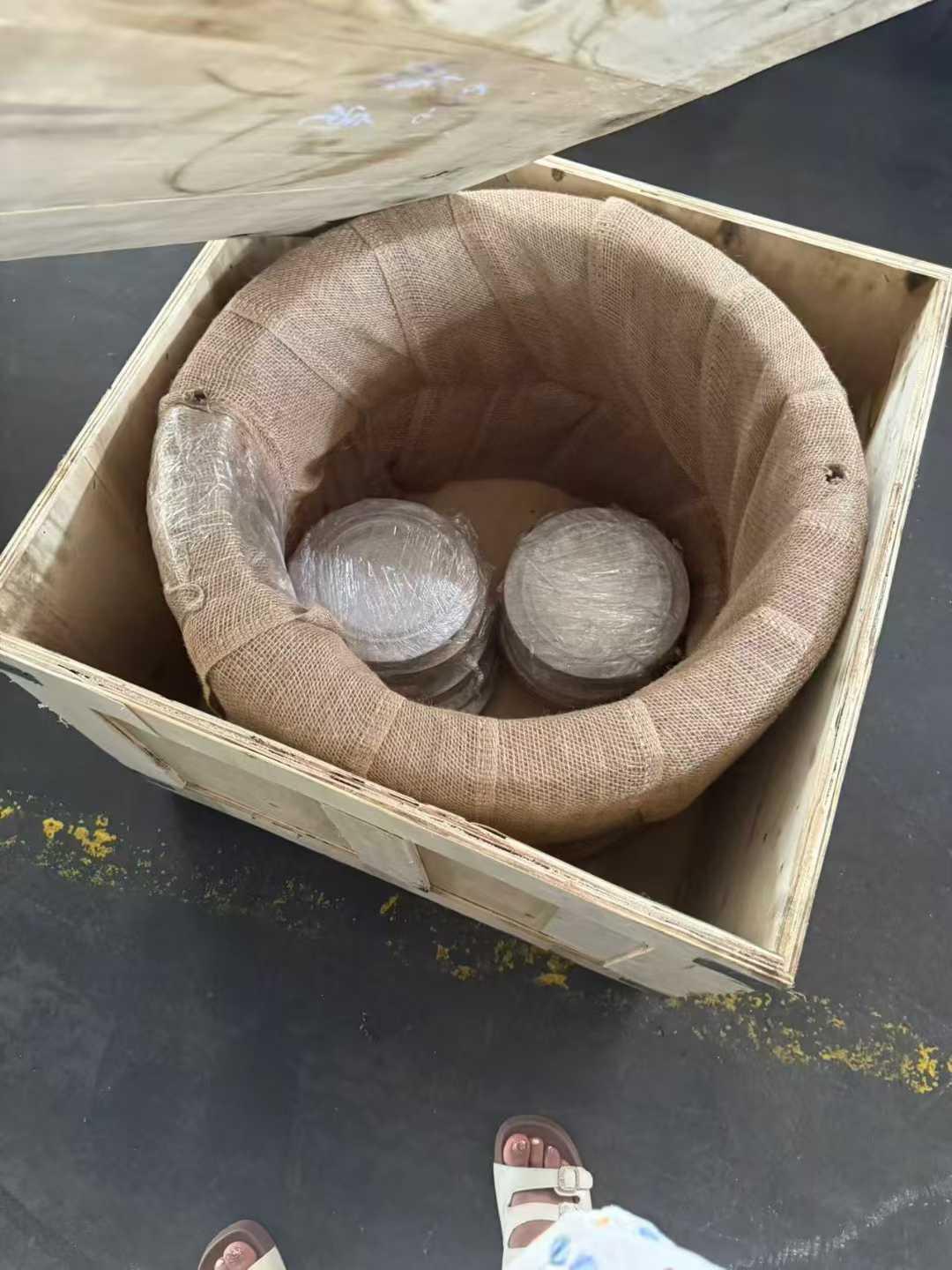

Today, domestic ring die manufacturer Huanmo Pellet Machine successfully completed the production of a batch of customized ring dies and officially shipped them to the European market. These ring dies were strictly developed according to European clients’ technical requirements, using premium alloy steel materials and precision machining processes to ensure high wear resistance, long service life, and stable production efficiency, meeting the demands of advanced European feed production lines.

As the global feed industry evolves towards intelligent and efficient operations, the quality of ring die—core components of pellet machines—directly impacts production capacity and product quality. The European-bound molds underwent rigorous quality inspections and met CE certification along with EU industry standards, demonstrating the competitiveness of Huanmo Pellet Machine in international markets.

A company spokesperson stated: “This collaboration marks our products gaining further recognition from European clients. Moving forward, we will continue optimizing technologies to provide more efficient customized solutions for global customers.”

The successful delivery not only solidifies Huanmo Pellet Machine’s position in the European market but also sets a new benchmark for Chinese smart manufacturing going global.