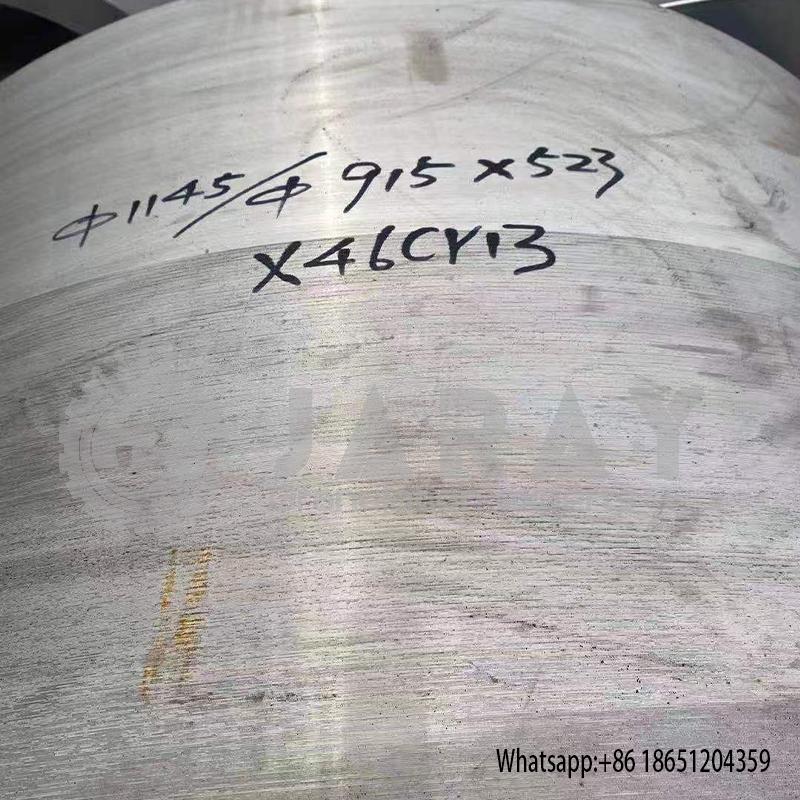

Initial forming of ring dies

The initial ring die forming process is the first critical step for stainless steel or alloy steel. Using precision forging or ring rolling techniques, the steel is shaped under high pressure and high temperature to create the initial ring die body and die profile. This process optimizes the material's internal grain flow and density, while ensuring a uniform and defect-free surface. This paves the way for subsequent finishing and ultimately ensures the ring die's superior wear, fatigue, and corrosion resistance.