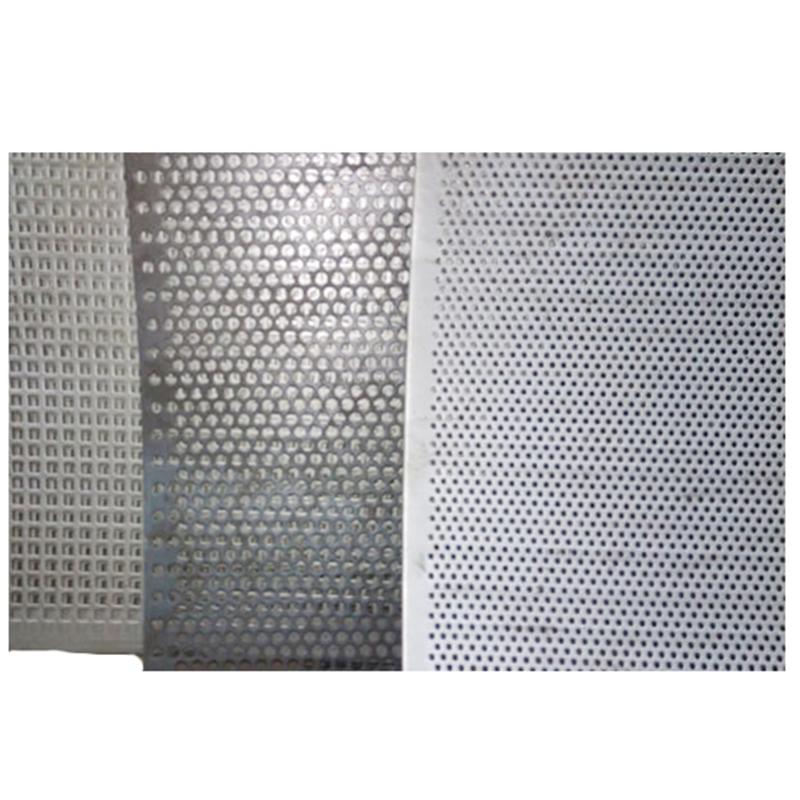

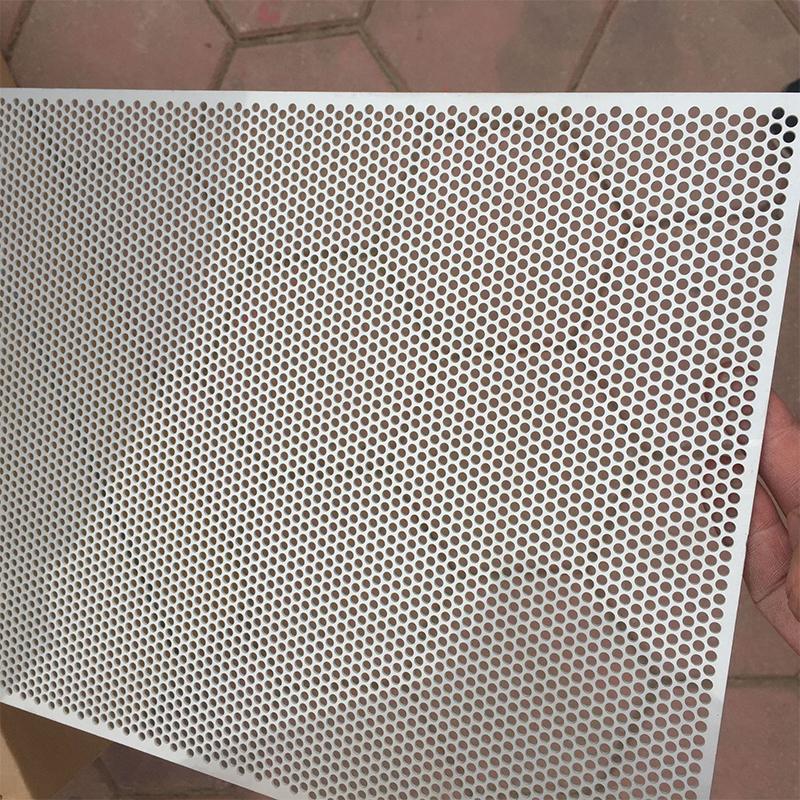

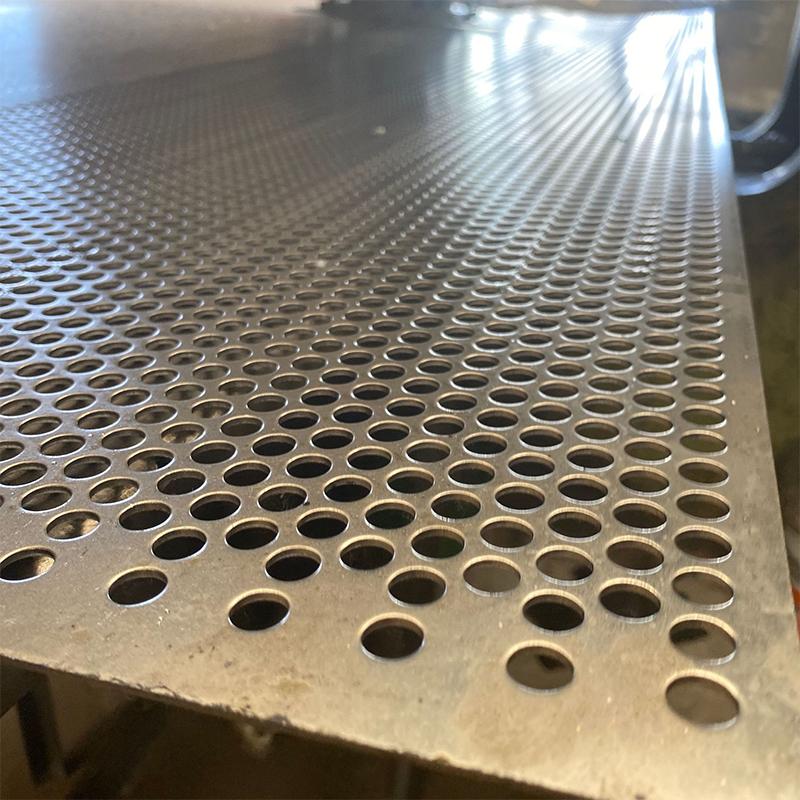

Hammer Mill Screens

Hammer mill screens are essential components of hammer mills, which are widely used in various industries such as agriculture, food processing, and biomass energy production. These screens play a critical role in determining the size and quality of the final product. This article provides a comprehensive overview of the function, features, applications, and maintenance of hammer mill screens.